Alright, my fellow future-tech enthusiasts! Have you ever paused to truly imagine a world where damaged organs are simply printed on demand, or where personalized tissues can heal us from within?

It sounds like something straight out of a sci-fi blockbuster, right? But what if I told you that thanks to incredible advancements in biomaterials, this future isn’t just a distant dream—it’s actively being built right now!

As someone who’s constantly got my finger on the pulse of breakthrough innovations, especially in the realm of regenerative medicine, I’ve been absolutely captivated by the latest trends in developing new biomaterials for bioprinting.

We’re talking about sophisticated bioinks that are not just biocompatible but are literally intelligent, mimicking our body’s own complex environments with astonishing precision.

From pioneering hybrid systems that blend multiple biopolymers to using smart materials that react dynamically to their surroundings, the possibilities are genuinely mind-blowing.

It’s a field experiencing explosive growth, with experts predicting major leaps in personalized implants and even organ transplantation very soon. Trust me, what’s happening behind the scenes is going to reshape healthcare as we know it, and I’m here to give you the inside scoop on how these revolutionary materials are making the impossible possible.

Ready to dive into the future of medicine with me? Let’s uncover the exact details.Alright, my fellow future-tech enthusiasts! Have you ever paused to truly imagine a world where damaged organs are simply printed on demand, or where personalized tissues can heal us from within?

It sounds like something straight out of a sci-fi blockbuster, right? But what if I told you that thanks to incredible advancements in biomaterials, this future isn’t just a distant dream—it’s actively being built right now!

As someone who’s constantly got my finger on the pulse of breakthrough innovations, especially in the realm of regenerative medicine, I’ve been absolutely captivated by the latest trends in developing new biomaterials for bioprinting.

We’re talking about sophisticated bioinks that are not just biocompatible but are literally intelligent, mimicking our body’s own complex environments with astonishing precision.

From pioneering hybrid systems that blend multiple biopolymers to using smart materials that react dynamically to their surroundings, the possibilities are genuinely mind-blowing.

It’s a field experiencing explosive growth, with experts predicting major leaps in personalized implants and even organ transplantation very soon. Trust me, what’s happening behind the scenes is going to reshape healthcare as we know it, and I’m here to give you the inside scoop on how these revolutionary materials are making the impossible possible.

Ready to dive into the future of medicine with me? Let’s uncover the exact details.

Unlocking Life’s Code: The Incredible Science of Bioinks

Mimicking Nature’s Design: The Quest for Perfect Biocompatibility

When I first started diving deep into the world of bioprinting, one of the things that immediately blew my mind was the sheer ingenuity behind creating materials that our bodies don’t just tolerate, but actually embrace.

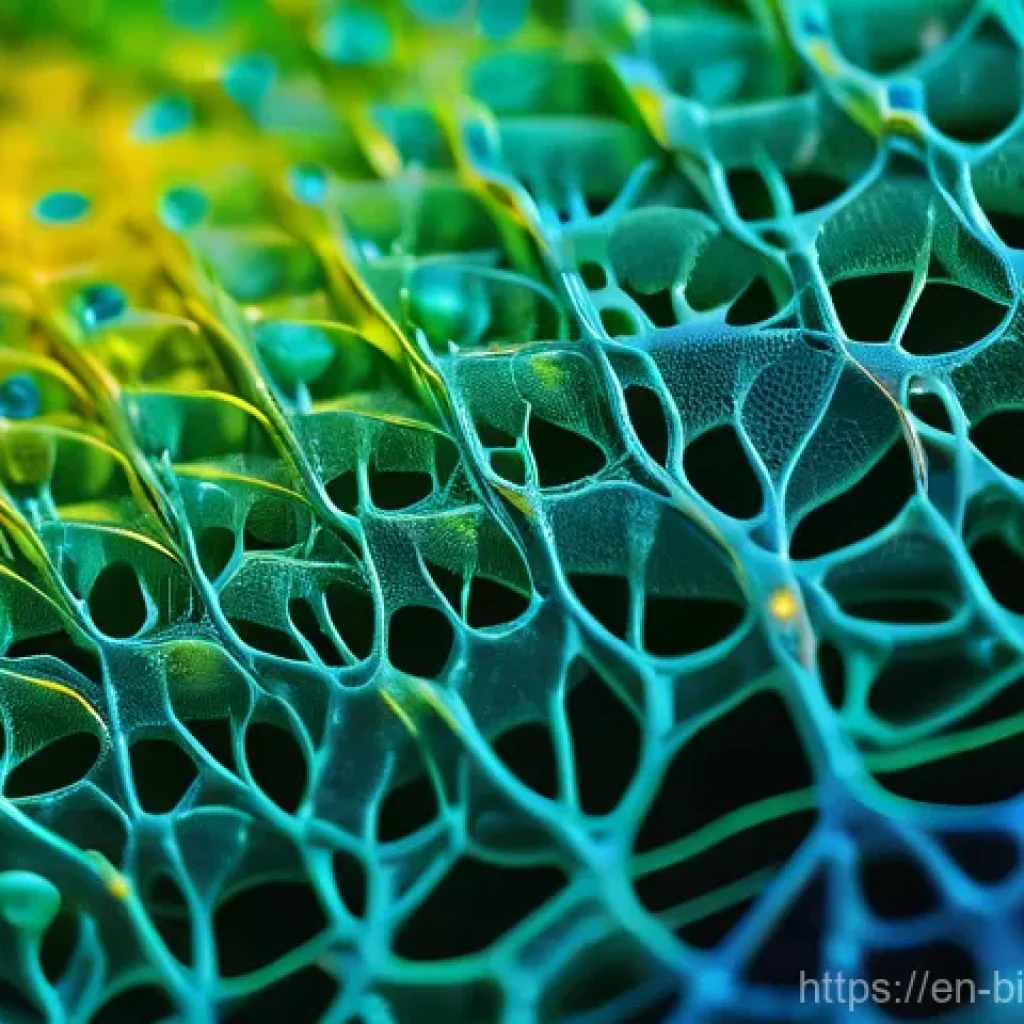

We’re not talking about just any old plastic here; bioinks are truly special. Imagine trying to build a tiny house that’s going to become a part of your garden, and you need to make sure the plants and soil are happy with it.

That’s kind of what scientists are doing, but inside us! They’re looking for materials that are not only squishy enough to print with incredible precision – think of squeezing toothpaste, but way more delicate – but also completely non-toxic and biodegradable, meaning they can break down harmlessly in the body over time as new tissue grows.

It’s a delicate dance, balancing printability with biological function, and honestly, seeing the progress being made is genuinely awe-inspiring. I remember chatting with a researcher who compared it to designing a microscopic, self-assembling LEGO set for cells.

The goal? To trick our cells into thinking these bioinks are just another part of their natural environment, allowing them to thrive, multiply, and eventually form functional tissue.

It’s like creating the perfect nurturing environment for life itself, right there in a petri dish or even directly in the body. The journey to find that “perfect” bioink is an ongoing marathon, but every new discovery brings us closer to a future where rejection is a thing of the past.

Beyond Simple Scaffolds: The Smart Materials Revolution

But here’s where it gets even more exciting: bioinks aren’t just passive scaffolds anymore. Oh no, we’re officially in the era of “smart materials”! This is where my tech-nerd heart truly sings.

Imagine a material that can change its properties based on cues from the body – perhaps getting stiffer as bone cells start to grow, or releasing growth factors exactly when and where they’re needed.

It’s like having a material that’s not just a blueprint, but an active participant in the healing process. These intelligent bioinks can respond to things like temperature, pH levels, or even mechanical stress, dynamically adapting to the ever-changing environment within our bodies.

Think about a personalized knee cartilage repair: instead of just a static patch, what if the implanted material could encourage cells to lay down new, healthy cartilage specific to your body’s needs, then gently degrade as your own tissue takes over?

That’s the power of these smart materials. From hydrogels that stiffen under UV light to polymers that release therapeutics on demand, the level of control and interaction we’re achieving is genuinely revolutionary.

I’ve heard stories from colleagues in the field about how these materials are literally “teaching” cells what to do, guiding their development and regeneration.

It’s not just science; it feels like artistry, sculpting life with precision and intelligence.

Building with Biomaterials: Hybrid Systems and Multi-Material Bioprinting

The Synergy of Polymers: Blending for Better Outcomes

If you’ve ever tried baking, you know that sometimes combining different ingredients gives you a far superior result than just using one. The same principle applies to bioprinting, but on a much more sophisticated scale.

We’re seeing incredible breakthroughs in “hybrid systems” where scientists are blending multiple biopolymers to create bioinks with a combination of desired properties.

Think about it: one polymer might offer fantastic structural integrity, while another provides the perfect environment for cell adhesion and growth, and yet another could be engineered for controlled drug release.

By carefully selecting and combining these different components, researchers are essentially custom-crafting materials that can meet the incredibly complex demands of different tissues and organs.

It’s a far cry from the early days when we were just experimenting with single materials. Now, it’s about synergy – making 1+1 equal way more than 2. I’ve personally seen presentations where researchers are using a cocktail of natural polymers like collagen and gelatin, mixed with synthetic ones like PLGA, to create bioinks that mimic the mechanical properties of a bone and the biological activity of soft tissue all at once.

The level of customization this allows is simply staggering, opening doors to previously unimaginable applications. It truly feels like we’re moving from a one-size-fits-all approach to highly personalized solutions, thanks to these ingenious hybrid strategies.

Customizing for Complexity: From Organs to Individual Cells

The human body is an absolute masterpiece of intricate design, with different tissues and organs possessing unique cellular architectures, mechanical properties, and biological functions.

Trying to replicate that complexity with a single material is like trying to paint a masterpiece with just one color. This is where multi-material bioprinting comes into its own.

Imagine being able to print a heart valve where each distinct layer – the fibrous annulus, the delicate leaflets, the vascular network – is laid down with a different bioink, each specifically chosen for its unique properties.

It’s not just about printing a general shape anymore; it’s about printing functional complexity down to the cellular level. This could mean using one bioink that promotes nerve regeneration in one area, while an adjacent section uses a different bioink to encourage blood vessel formation.

It’s a painstaking process, requiring incredible precision and sophisticated printing technology, but the potential rewards are immense. I recently read about a team that managed to bioprint a tiny kidney-like structure with multiple cell types and distinct functional zones – a feat that was simply unthinkable just a few years ago.

The ability to precisely control the placement of different cells and biomaterials allows us to reconstruct tissues with an unprecedented level of biological accuracy, moving us closer to fully functional, patient-specific organs.

Dynamic Materials: When Bioinks Respond to Their Environment

Responding to the Body: Stimuli-Responsive Bioinks

Have you ever wished a medical implant could adapt to your body’s changing needs, rather than remaining a static foreign object? Well, get ready, because stimuli-responsive bioinks are making that a reality.

These incredible materials are engineered to react to specific triggers, transforming their properties in response to physiological cues. Think about it: a bioink that stiffens or softens based on mechanical load, encouraging bone cells to grow stronger where needed, or cartilage cells to remain flexible in joints.

Or perhaps a bioink that releases a therapeutic drug only when it detects inflammation, targeting the problem area precisely and efficiently. We’re talking about materials that can change their shape, viscosity, or even their chemical composition when exposed to things like temperature fluctuations, pH changes, light, or electrical signals.

It’s like having miniature, responsive factories inside the body. I find this absolutely fascinating because it means we’re moving away from passive implants to active, interactive therapeutic agents.

Imagine a personalized wound dressing that could release antibiotics only when a bacterial infection is detected, thus preventing overuse and resistance.

The precision and specificity these materials offer are truly a game-changer for personalized medicine, pushing the boundaries of what we thought was possible for internal healing and reconstruction.

The Healing Touch: Self-Healing and Degradable Biomaterials

One of the biggest challenges in regenerative medicine is ensuring the long-term viability of implanted tissues. What if the very materials we implant could repair themselves, or gracefully step aside once their job is done?

Enter self-healing and degradable biomaterials. Self-healing bioinks are like the ultimate repair crew, designed with internal mechanisms to mend small damages or micro-cracks that might occur post-implantation, thereby extending the lifespan and functionality of the bioprinted tissue.

It’s akin to having a tiny, biological self-repair kit embedded within the material itself. Then there are degradable biomaterials, which are equally vital.

These aren’t meant to stay forever; their purpose is to provide a temporary scaffold, guiding the body’s own cells to regenerate new tissue. Once the new tissue has matured and is strong enough, the biomaterial gracefully breaks down and is safely absorbed or excreted by the body.

This “transient” approach minimizes the long-term risks associated with permanent implants and ensures that what remains is purely natural, functional tissue.

From my perspective, this is a huge leap forward. It addresses the natural fear of foreign objects remaining in the body and champions a truly regenerative approach, where the body does most of the healing, simply guided and supported by these intelligent materials.

It’s about empowering our own biology to do what it does best.

Navigating the Future: Overcoming Bioprinting’s Grand Challenges

Quality Control and Standardization: Ensuring Safety and Efficacy

As amazing as these advancements are, bringing them from the lab to actual patients comes with some pretty hefty hurdles. One of the biggest is ensuring rigorous quality control and standardization.

When you’re talking about something that’s going to be implanted into a human body, there’s absolutely no room for error. Every batch of bioink, every printed scaffold, needs to meet incredibly strict specifications for sterility, consistency, mechanical properties, and cellular compatibility.

It’s a monumental task to develop reliable testing protocols and regulatory frameworks that can keep pace with the rapid innovation in this field. I’ve heard researchers express frustration over the lack of universal standards, which can slow down progress.

Imagine trying to build a complex engine without standardized parts; it would be a nightmare! The scientific community, alongside regulatory bodies like the FDA, is working tirelessly to establish these benchmarks.

This involves everything from ensuring the biological source materials are ethically and safely acquired, to validating the printing process itself, and finally, proving that the bioprinted tissue behaves exactly as expected over time.

It’s a meticulous, painstaking process, but absolutely essential for patient safety and for building trust in these revolutionary technologies.

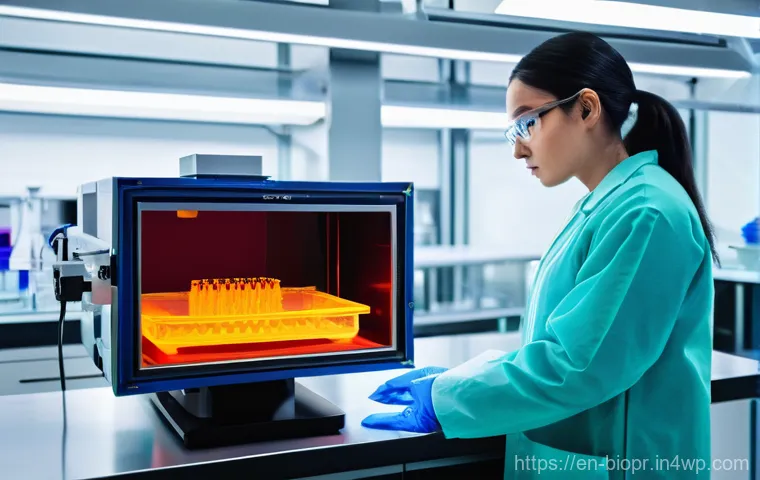

Scaling Up: From Lab Bench to Operating Room

Another major challenge, and one that often gets overlooked in the excitement of discovery, is scaling up production. It’s one thing to print a tiny piece of tissue in a highly controlled lab environment for research purposes; it’s an entirely different beast to produce hundreds or thousands of patient-specific implants or even complex organs on an industrial scale.

This requires sophisticated automated systems, cost-effective manufacturing processes, and efficient ways to handle and sterilize biological materials without compromising their integrity.

Think about the logistics involved in mass-producing something as delicate and biologically active as a printed human tissue! The transition from a proof-of-concept experiment to a clinically viable product demands a complete rethinking of manufacturing pipelines.

This often means huge investments in infrastructure, advanced robotics, and highly skilled personnel. It’s not just about the science anymore; it’s about engineering, logistics, and economics.

I’ve often wondered about the practicalities of a “bio-factory” and the sheer volume of resources and expertise it would require. The journey from a promising lab result to a readily available therapeutic option in hospitals around the world is long and fraught with challenges, but the drive to make these life-saving technologies accessible is incredibly strong.

My Personal Thoughts: Why This Bioprinting Revolution Matters to All of Us

A Glimpse into the Future: Personalized Medicine’s New Frontier

Honestly, talking about bioprinting and these incredible biomaterials gets me genuinely excited for the future of healthcare. It’s not just abstract science; it’s about a tangible path to a healthier, more vibrant life for countless individuals.

When I imagine personalized medicine, this is exactly what I picture: treatments so tailored to an individual that they feel like they were custom-made, because, well, they literally are!

Imagine a future where a child born with a heart defect doesn’t have to wait for a donor or undergo multiple invasive surgeries, but instead receives a perfectly matched, bioprinted cardiac patch that grows with them.

Or an athlete recovering from a severe knee injury who gets a new piece of cartilage perfectly matched to their own unique anatomy and needs, accelerating their recovery and reducing long-term complications.

This isn’t just about replacing diseased parts; it’s about restoring function, enhancing quality of life, and pushing the boundaries of what human longevity and health can look like.

I truly believe that the advancements we’re seeing today in biomaterials for bioprinting are laying the groundwork for a medical paradigm shift, moving us from reactive treatments to proactive, regenerative solutions that truly leverage our body’s own incredible healing capabilities.

It’s a future where each person’s unique biology is the blueprint for their own healing.

The Ethical Compass: Navigating the Brave New World

Now, with such groundbreaking technology comes, quite naturally, a whole host of ethical considerations. It’s a conversation that absolutely needs to happen openly and thoughtfully.

As someone who’s always fascinated by the societal impact of new tech, I find myself pondering questions like: Who will have access to these advanced treatments?

How do we ensure equitable distribution and affordability, so this isn’t just a luxury for the privileged few? What are the implications of creating increasingly complex biological structures in a lab?

We’re not talking about simply printing a plastic widget; we’re talking about potentially printing functional tissues and eventually, organs. This raises profound questions about the definition of life, human enhancement, and the very essence of what it means to be human.

I often discuss these topics with friends and colleagues, and there are no easy answers. It’s crucial that as the science progresses, so too does our collective ethical dialogue, ensuring that we develop these technologies responsibly and with the best interests of humanity at heart.

It’s a brave new world, and while the scientific potential is exhilarating, guiding it with a strong ethical compass is paramount.

The Horizon Ahead: Emerging Trends and What’s Next in Bioprinting

4D Bioprinting: Adding Time as a Dimension

If 3D bioprinting wasn’t mind-boggling enough, get ready for 4D bioprinting! This isn’t a typo; it’s an incredibly exciting concept where the “fourth dimension” is time.

Imagine printing a structure that then changes shape, function, or even self-assembles over time in response to specific environmental stimuli. This adds an entirely new layer of complexity and functionality to bioprinted tissues.

For instance, a blood vessel printed as a flat sheet could then coil into a tubular structure within the body, or a scaffold could slowly transform its pore size as new cells migrate in.

This dynamic adaptability could solve some tricky problems, especially when trying to replicate the intricate, changing environments of living tissues.

It’s like creating a biological origami, where the material folds and reforms itself after printing. I’ve seen some incredible examples of this, from hydrogels that respond to changes in temperature or pH, to structures that exhibit pre-programmed deformation.

The ability to control the post-printing evolution of a biomaterial opens up possibilities for creating even more sophisticated and functionally robust biological constructs, moving us closer to truly mimicking the dynamic nature of living systems.

It’s a field that feels straight out of a futuristic movie, and it’s happening now.

AI and Machine Learning: Accelerating Discovery

Behind every major scientific breakthrough often lies powerful computational tools, and bioprinting is no exception. Artificial intelligence (AI) and machine learning (ML) are rapidly becoming indispensable in accelerating the discovery and optimization of new biomaterials and printing processes.

Imagine trying to manually test thousands of different bioink formulations to find the optimal one for a specific tissue. It would take decades! AI algorithms, however, can analyze vast datasets, predict material properties, and even design novel bioink compositions with unprecedented speed and accuracy.

They can optimize printing parameters, simulate tissue growth, and even predict the long-term behavior of bioprinted implants, drastically reducing the trial-and-error often associated with research.

This synergy between biology, engineering, and computer science is genuinely revolutionary. I’ve talked to researchers who swear by AI for screening potential new materials, saving them countless hours and resources.

It’s like having an incredibly intelligent assistant who can sift through mountains of data and pinpoint the most promising avenues for exploration. This isn’t just about making things faster; it’s about enabling discoveries that might have been impossible for humans alone to conceive.

The convergence of AI and bioprinting is pushing the boundaries of what’s possible, promising to fast-track the development of next-generation regenerative therapies.

The Investment and Impact: Bringing Bioprinting to Life

Funding the Future: Where the Dollars Are Going

It’s no secret that groundbreaking research requires significant investment, and the field of biomaterials for bioprinting is attracting some serious capital.

We’re talking about funding flowing in from various sources – government grants, venture capital firms, pharmaceutical giants, and even philanthropic organizations.

This influx of money is a clear indicator of the immense potential perceived in this sector. Major biotech companies are heavily investing in R&D, seeing the long-term therapeutic and economic benefits.

Start-ups focusing on novel bioinks, advanced bioprinters, and specialized tissue engineering are popping up, driven by innovative ideas and a desire to revolutionize healthcare.

I often track investment trends, and the consistent growth in funding for regenerative medicine, particularly bioprinting, is truly remarkable. This capital is crucial not only for fundamental research but also for the monumental task of clinical trials, regulatory approvals, and ultimately, scaling up production.

It signals a collective belief that this isn’t just a fleeting scientific fad, but a foundational shift in how we approach disease and injury. It’s exciting to see money being poured into areas that could fundamentally change lives for the better, making a tangible difference to people around the globe.

Beyond Organ Transplants: A Broader Therapeutic Horizon

When most people hear “bioprinting,” their minds often jump straight to printing entire organs, and while that’s certainly an ultimate goal, the immediate therapeutic horizon is far broader and equally impactful.

Bioprinting isn’t just about replacing a kidney; it’s about creating customized skin grafts for burn victims, printing intricate drug delivery systems, developing new models for drug discovery and toxicology testing (reducing the need for animal testing!), and even creating better implants for orthopedic repairs.

The applications are incredibly diverse. Imagine a future where pharmaceutical companies can test new drugs on bioprinted human liver tissue, getting far more accurate results than traditional animal models.

Or where diabetes patients could receive bioprinted pancreatic islets to restore insulin production. These “smaller” applications, while perhaps less dramatic than a full organ transplant, are absolutely crucial and are much closer to clinical reality.

I believe it’s this breadth of application, from personalized medicine to accelerated research, that makes bioprinting such a powerful and transformative technology.

It’s a tool that can address a multitude of medical challenges, pushing the boundaries of what we thought was possible in healing and health.

| Bioink Type | Key Properties & Benefits | Potential Applications |

|---|---|---|

| Hydrogels (e.g., Alginate, Gelatin) | High biocompatibility, tunable mechanical properties, excellent cell encapsulation. | Soft tissue engineering (cartilage, muscle), drug delivery, wound healing. |

| Synthetic Polymers (e.g., PLGA, PCL) | High mechanical strength, controlled degradation rates, easy processability. | Bone and cartilage regeneration, surgical implants, scaffolding. |

| Ceramic-based Bioinks (e.g., Hydroxyapatite) | Osteoconductive (bone growth promoting), high stiffness. | Bone defect repair, dental implants, orthopedic applications. |

| Hybrid Bioinks (combinations) | Combines advantages of multiple materials (e.g., strength + biocompatibility). | Complex tissue structures (e.g., osteochondral tissue), multi-functional implants. |

| Smart/Responsive Bioinks | Changes properties based on stimuli (temp, pH, light, mechanical force). | Dynamic tissue models, on-demand drug release, adaptable implants. |

Wrapping Things Up

As we wrap up our deep dive into the mesmerizing world of bioinks and bioprinting, I hope you feel as energized and hopeful about the future as I do. It’s truly a frontier where science fiction is rapidly becoming scientific fact, pushing the boundaries of what we thought was medically possible. From creating materials that perfectly mimic our own tissues to the incredible potential of personalized organs, the journey ahead is brimming with exciting possibilities. Keep an eye on this space, because the next big breakthrough might just be around the corner, ready to reshape healthcare as we know it!

Useful Information to Know

1.

If you’re fascinated by this field and considering a career, look into interdisciplinary programs that combine biology, engineering, and computer science. The future of bioprinting thrives on diverse skill sets, from material scientists to AI specialists. It’s a truly collaborative environment.

2.

Stay updated with scientific journals and reputable tech news outlets that cover regenerative medicine. This field evolves incredibly fast, and keeping a pulse on the latest discoveries, from new bioink formulations to clinical trial progress, is key to understanding its trajectory.

3.

Consider the ethical implications alongside the scientific advancements. As we gain the power to create complex biological structures, engaging in thoughtful discussions about accessibility, regulation, and societal impact is more important than ever. Your voice matters in shaping this future.

4.

Don’t just think “organs”! While full organ bioprinting is a long-term goal, many immediate and impactful applications of bioinks and bioprinting involve smaller-scale tissue repair, drug testing models, and personalized implants, which are already making a difference.

5.

Supporting research and development in regenerative medicine, whether through advocacy or by staying informed, plays a crucial role. Public awareness and interest can drive funding and policy, accelerating the pace at which these life-changing technologies reach those who need them most.

Key Takeaways

What we’ve explored today isn’t just cutting-edge science; it’s a profound paradigm shift in how we approach healing and longevity. The revolution of bioinks and bioprinting is fundamentally reshaping our understanding of regenerative medicine, moving us from merely treating symptoms to actively regenerating and restoring functional tissues. We’ve seen how these intelligent materials are designed to be perfectly biocompatible, dynamically responsive to our bodies, and even self-healing, offering an unparalleled level of personalization in therapeutic solutions. The blending of various polymers, the advent of multi-material printing, and the exciting frontier of 4D bioprinting highlight an ongoing quest for materials that can truly mimic and integrate with the complexity of life itself. While significant challenges remain in terms of standardization, scaling up, and navigating ethical landscapes, the sheer pace of innovation, fueled by substantial investment and the power of AI, signals a future where organ shortages could become a relic of the past, and personalized treatments are the norm. This isn’t just about printing body parts; it’s about empowering our own biology to heal and thrive in ways we once only dreamed of, ushering in an era of unprecedented health and well-being for everyone.

Frequently Asked Questions (FAQ) 📖

Q: What exactly are “smart” biomaterials or “bioinks” that you mentioned?

A: Oh, this is where the magic really starts to happen! When I talk about “smart” biomaterials or “intelligent bioinks,” I’m referring to a revolutionary class of materials that are designed to do so much more than just sit there and hold cells.

Think of them like tiny, advanced engineers for our bodies. These incredible materials have the unique ability to literally react and change their properties in response to specific cues in their environment.

We’re talking about things like subtle shifts in temperature, pH levels, or even electrical and magnetic fields. It’s truly wild! What I’ve personally found fascinating is how they’re being crafted to perfectly mimic our body’s own complex natural environments, the extracellular matrix, with astonishing precision.

This isn’t just about structural support; it’s about actively guiding cell behavior. They can promote cell adhesion, encourage growth, direct differentiation into specific tissue types, and even facilitate migration.

Some can even release therapeutic agents in a controlled way, exactly when and where they’re needed. It’s like having a personalized, dynamic scaffold that helps our cells build and heal themselves, making truly functional and responsive tissues a tangible reality.

Q: How far are we from seeing fully bioprinted organs for human transplantation? It sounds amazing but also incredibly complex!

A: That’s a fantastic question, and one I get asked a lot! It absolutely sounds like science fiction, doesn’t it? As someone who follows this space closely, I can tell you we’re making tremendous strides, but it’s also a journey with its fair share of hurdles.

Right now, the most significant applications for bioprinting involve creating smaller tissue models for drug screening, which is a huge win for pharmaceutical development, and for repairing specific tissues like bone, cartilage, or even skin grafts.

We’ve even seen researchers successfully bioprint liver-like structures that perform critical functions! However, scaling up to a fully functional, transplantable human organ, say a heart or a kidney, is a monumental engineering and biological challenge.

The biggest sticking points, from my perspective, are creating intricate vascular networks to deliver nutrients and remove waste throughout a large organ, ensuring the printed structures have the necessary mechanical properties to function under the body’s stresses, and, of course, the incredibly rigorous regulatory and ethical landscapes we need to navigate.

While some experts have optimistically projected bioprinted organs in animals within a decade or so, and clinical trials for cell-containing implants potentially much sooner, the transition to full human organ transplantation is likely still some years away.

It’s less of an “if” and more of a “when,” but it’s going to take continued innovation, dedication, and a clear pathway for clinical translation.

Q: Beyond full organs, how will advanced biomaterials in bioprinting specifically impact personalized medicine for everyday people?

A: This is where I get really excited, because the impact on personalized medicine is going to be profound and, honestly, much closer than many people realize!

While the idea of a fully printed organ captures the imagination, the real-world applications for everyday folks are going to revolutionize how we approach health and healing.

Imagine, for instance, patient-specific implants that perfectly match your unique anatomy, whether it’s a tiny piece of cartilage for a damaged joint or a custom bone graft that integrates seamlessly with your existing tissue.

This level of precision, tailored just for you, means better outcomes and faster recovery. Then there’s the incredible potential for intelligent drug delivery systems.

We’re talking about smart patches that release medication exactly when your body needs it, at the right dosage, and directly to the affected area, minimizing side effects.

I’ve personally seen research on things like bioprinted wound-healing patches and even antimicrobial solutions for piercings – simple but game-changing!

Plus, the ability to create highly accurate human tissue models for drug testing means safer, more effective medications developed faster, reducing reliance on animal testing.

Combining a patient’s own cells with these advanced biomaterials also dramatically reduces the risk of immune rejection, which is a massive hurdle in traditional transplantation.

For me, it’s about transforming healthcare from a “one-size-fits-all” approach to truly tailored treatments that improve our quality of life in countless ways.