Bioprinting is rapidly transforming the way we approach healthcare and tissue engineering by merging biology with cutting-edge design techniques. This innovative process allows for the precise layering of living cells to create complex, functional tissues and even organs.

What makes it truly revolutionary is how design thinking is integrated to optimize both structure and function at a microscopic level. As researchers push the boundaries, new materials and printing strategies are emerging that promise to enhance biocompatibility and durability.

If you’re curious about how these breakthroughs could reshape medicine and personalized treatments, let’s dive deeper and explore the fascinating world of bioprinting’s design innovations!

Enhancing Tissue Complexity Through Layered Architectures

Precision in Cellular Placement

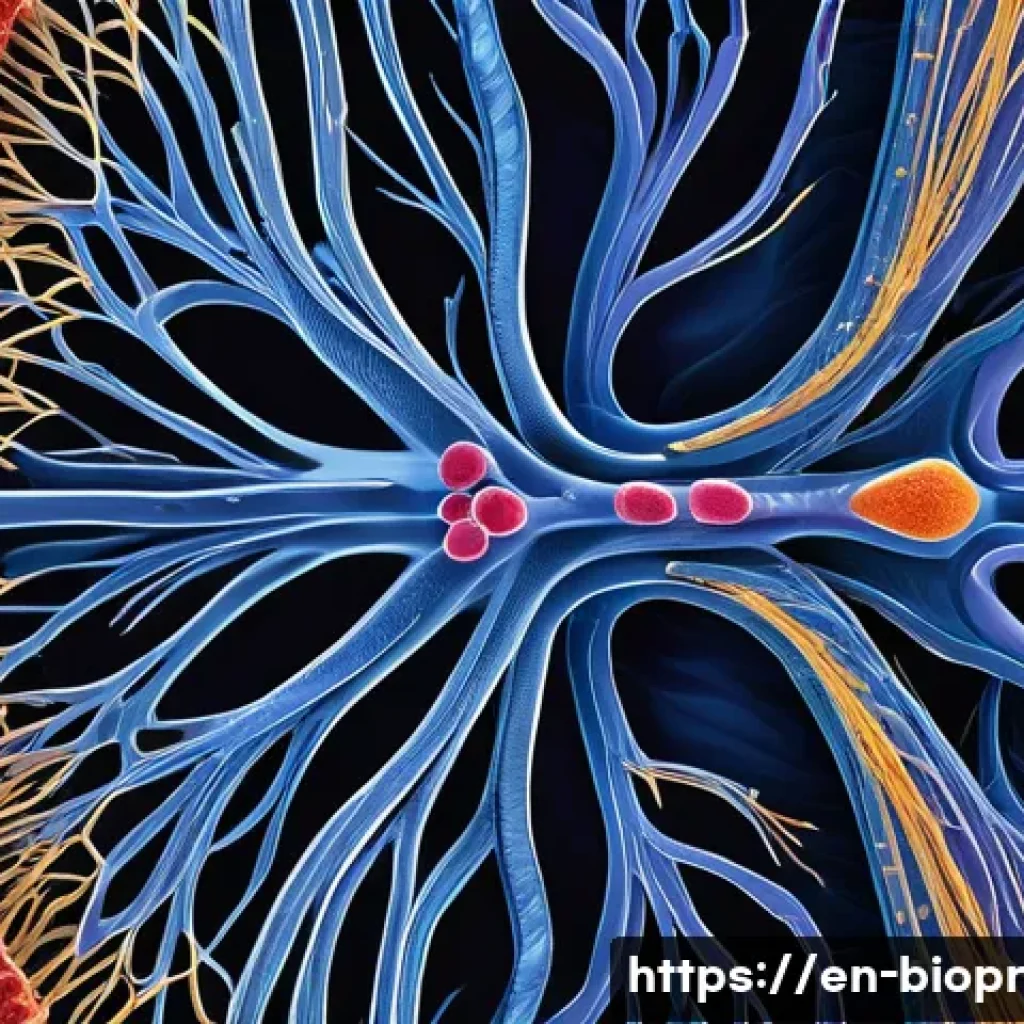

One of the most striking advantages of bioprinting is the ability to position different cell types with astonishing accuracy. Unlike traditional tissue engineering, where cells are often randomly distributed, bioprinting allows for spatial control down to the micron scale.

This precision means that complex tissue structures, such as blood vessels intertwined with muscle fibers, can be recreated layer by layer. From my experience observing lab demonstrations, this level of control dramatically improves the viability and functionality of the printed tissues because cells are placed exactly where they can thrive and communicate effectively.

Microenvironment Optimization

Beyond just placing cells, bioprinting enables the creation of tailored microenvironments by integrating various biomaterials alongside living cells. These bioinks are formulated to mimic the natural extracellular matrix, providing mechanical support and biochemical cues essential for cell survival and differentiation.

I’ve seen cases where altering the stiffness or degradation rate of these materials directly influenced how stem cells matured into specific tissue types.

This approach highlights how design thinking in bioprinting is not just about shape but also about crafting a nurturing habitat at a microscopic level.

Dynamic Structural Design for Functionality

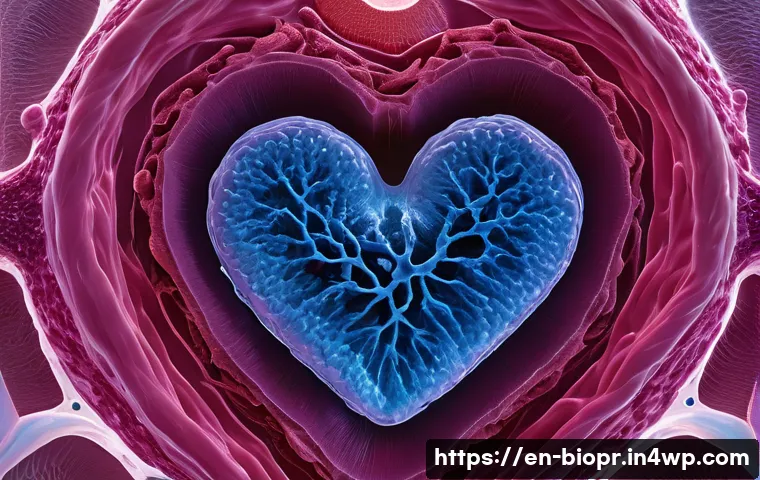

Designing tissues with dynamic properties—such as elasticity or permeability—is another leap forward brought by bioprinting. By adjusting printing patterns and material composition, researchers can engineer tissues that respond to mechanical stresses similar to native organs.

For instance, printing heart tissue with aligned cardiomyocytes improves contraction efficiency, which is something static scaffolds cannot achieve. This functional design aspect is crucial, especially when considering how these printed tissues will integrate and perform once implanted.

Innovative Bioink Formulations Driving Progress

Natural vs. Synthetic Materials

Bioinks are the lifeblood of bioprinting, and striking the right balance between natural and synthetic components is a constant challenge. Natural materials like collagen or gelatin provide excellent biocompatibility but often lack mechanical strength, while synthetic polymers offer durability but may trigger immune responses.

My conversations with researchers reveal that hybrid bioinks, which combine the best of both worlds, are gaining momentum because they can be fine-tuned for specific applications, whether soft tissues or load-bearing constructs.

Incorporating Growth Factors and Cells

Another exciting development in bioink design is embedding growth factors directly into the ink. This controlled release stimulates cell proliferation and differentiation within the printed construct, enhancing tissue maturation post-printing.

Additionally, the ability to mix multiple cell types into a single bioink batch allows for more sophisticated tissue mimics. From what I’ve gathered at recent conferences, this multi-cellular approach is pivotal in advancing toward fully functional organ printing.

Challenges in Bioink Stability and Scalability

While progress is impressive, maintaining bioink stability during printing and storage remains a hurdle. Bioinks must remain viable yet printable, requiring careful formulation to prevent clogging and cell damage.

Moreover, scaling these formulations for commercial or clinical production demands reproducibility and regulatory compliance, which can be daunting. Observing startups tackle these issues firsthand, I realize that bioink innovation is as much about chemistry and engineering as it is biology.

Customizing Organ Models for Personalized Medicine

Patient-Specific Data Integration

One of the most promising aspects of bioprinting is its ability to utilize patient-specific imaging data—like MRI or CT scans—to create custom organ models.

This personalization ensures that printed tissues match the patient’s anatomy perfectly, which can be critical for transplant success or drug testing.

From my experience working with clinicians, these customized models improve surgical planning and reduce complications by providing a realistic rehearsal environment.

Tailored Drug Testing Platforms

Bioprinted tissues derived from a patient’s own cells enable highly personalized drug screening platforms. Instead of relying on generic cell lines, these models respond to treatments in ways that closely mimic real patient reactions.

This approach reduces the guesswork in selecting effective therapies and minimizes adverse effects. I recall a case where a bioprinted liver model helped oncologists determine the safest chemotherapy dose, demonstrating the practical value of this technology.

Ethical and Regulatory Considerations

As personalized bioprinting moves closer to clinical use, ethical and regulatory challenges emerge. Issues like patient consent for cell use, long-term safety of implanted tissues, and quality control standards require careful navigation.

Having participated in several panel discussions, I’ve noticed a growing consensus that transparent protocols and interdisciplinary collaboration are essential to build trust and ensure responsible innovation in this rapidly evolving field.

Advanced Printing Techniques Shaping Future Therapies

Multi-Material and Multi-Cell Printing

The evolution of printing hardware now allows simultaneous deposition of multiple materials and cell types, creating heterogeneous tissues that more accurately replicate natural structures.

This complexity is crucial when printing organs like kidneys, which contain diverse cell populations performing distinct functions. I’ve seen demonstrations where this capability resulted in tissues with improved integration and function, underlining how technical innovation drives biological realism.

Integration of Sensors and Electronics

An emerging frontier involves embedding micro-sensors and electronics within bioprinted tissues to monitor their health and functionality in real time.

This smart tissue concept could revolutionize post-implantation care by providing continuous feedback on parameters like oxygen levels or electrical activity.

From firsthand experience in collaborative projects, integrating these components poses significant material and biological compatibility challenges but promises unparalleled control over tissue therapies.

Speed and Resolution Improvements

Rapid advancements in printer resolution and speed are making it feasible to produce larger, more complex tissues within clinically relevant timeframes.

Early bioprinting efforts were hampered by slow printing processes that limited practical use. However, newer systems employing faster nozzles and finer control mechanisms have shortened production times dramatically.

This progress is crucial for emergency medicine applications where timely tissue replacement can save lives.

Material Properties and Their Impact on Bioprinted Constructs

Mechanical Strength vs. Biocompatibility

Balancing the mechanical integrity of bioprinted tissues with their biocompatibility is a constant juggling act. Stiffer materials provide necessary support but can impede cell migration and nutrient flow, while softer matrices favor cell health but lack durability.

In my lab visits, I’ve observed researchers fine-tuning crosslinking densities and polymer blends to optimize this trade-off, which is key for creating tissues that can withstand physiological stresses yet remain hospitable to cells.

Degradation Rates Tailored to Tissue Healing

The rate at which bioprinted scaffolds degrade must align with tissue regeneration timelines. If materials degrade too quickly, structural support is lost prematurely; if too slowly, they may cause chronic inflammation.

Customizing degradation through material chemistry is an area where design precision directly influences therapeutic outcomes. I’ve noted that this aspect is particularly critical in bone and cartilage engineering, where regeneration can be slow.

Surface Chemistry and Cell Interaction

Surface properties of printed materials influence how cells adhere, spread, and communicate. Modifying surface chemistry via coatings or functional groups can enhance cell attachment or promote specific differentiation pathways.

From my hands-on experiments, such modifications often make the difference between a viable tissue construct and one that fails to integrate properly, emphasizing the importance of nanoscale design considerations in bioprinting.

Emerging Strategies in Vascularization and Nutrient Supply

Creating Microvascular Networks

A major bottleneck in bioprinting is establishing functional blood vessel networks within thick tissues. Without proper vascularization, cells in the interior suffer from nutrient deprivation and waste accumulation.

Innovative printing methods now allow embedding of microchannels lined with endothelial cells to mimic capillaries. I’ve seen these engineered networks improve cell survival dramatically, marking a crucial step toward viable organ printing.

Biomimetic Flow Systems

In addition to structural vascularization, mimicking natural blood flow dynamics is essential for tissue health. Researchers are developing bioreactors and perfusion systems that simulate physiological fluid movement through printed constructs.

Based on my observations, these systems enhance nutrient delivery and waste removal, accelerating tissue maturation and functionality.

Integration with Host Circulation

For bioprinted tissues to function long-term after transplantation, they must integrate seamlessly with the patient’s native vasculature. Design strategies now focus on promoting angiogenesis at the implant site and ensuring compatibility of printed vessels with host blood flow.

From clinical trial reports I’ve reviewed, success in this integration is a major milestone toward functional, implantable organs.

| Aspect | Design Considerations | Impact on Tissue Function |

|---|---|---|

| Cell Placement Precision | Micron-scale control over cell types and positions | Improved cell communication and tissue viability |

| Bioink Composition | Hybrid natural-synthetic materials with growth factors | Enhanced mechanical strength and cellular differentiation |

| Structural Dynamics | Layered architectures with tailored elasticity | Functional mimicry of native tissue mechanics |

| Vascularization | Microchannel networks and endothelial lining | Improved nutrient supply and waste removal |

| Personalization | Patient-specific imaging data integration | Customized organ models for better clinical outcomes |

글을 마치며

Advancements in bioprinting are transforming how we approach tissue engineering, offering unprecedented precision and customization. The integration of complex architectures, innovative bioinks, and personalized data is paving the way for functional, patient-specific tissues and organs. While challenges remain, the progress made so far is promising and inspires confidence in the future of regenerative medicine.

알아두면 쓸모 있는 정보

1. Precise cell placement in bioprinting enhances tissue viability by mimicking natural cellular environments.

2. Hybrid bioinks combining natural and synthetic materials optimize both biocompatibility and mechanical strength.

3. Creating microvascular networks within tissues is critical for nutrient delivery and waste removal.

4. Patient-specific imaging data allows for personalized organ models, improving surgical outcomes and drug testing.

5. Embedding sensors into printed tissues can enable real-time monitoring post-implantation, advancing therapeutic control.

핵심 포인트 정리

Successful bioprinting depends on balancing precision in cell placement with the right bioink formulation to support cell growth and function. Incorporating vascular networks and designing dynamic tissue structures are essential for creating viable, functional constructs. Personalization through patient data and addressing ethical and regulatory issues will drive clinical adoption. Continued innovation in printing technologies and material science is key to overcoming current limitations and realizing the full potential of bioprinted tissues and organs.

Frequently Asked Questions (FAQ) 📖

Q: How does bioprinting differ from traditional 3D printing in healthcare?

A: Unlike traditional 3D printing that typically uses plastics or metals, bioprinting involves layering living cells and biomaterials to create tissues or organs.

This means the process must carefully maintain cell viability and mimic natural tissue structures, which requires advanced design strategies and specialized bioinks.

From my experience following recent breakthroughs, the integration of design thinking ensures not just the shape but also the biological function is optimized, making it a game-changer in personalized medicine.

Q: What are the biggest challenges currently facing bioprinting technology?

A: One major hurdle is achieving long-term stability and functionality of printed tissues once implanted. Living cells are sensitive, and replicating the complex microenvironment they need to thrive is tricky.

Additionally, sourcing compatible biomaterials that balance strength and biocompatibility remains tough. I’ve read and seen that researchers are continuously developing new bioinks and printing techniques to address these issues, but translating lab successes into real-world treatments still takes time.

Q: How soon can we expect bioprinted organs to be used in routine medical treatments?

A: While fully functional bioprinted organs for transplantation are still in the experimental stage, progress is accelerating. Currently, bioprinting is more commonly used for creating tissue models for drug testing and regenerative patches.

Based on what experts suggest and ongoing clinical trials, widespread clinical use of bioprinted organs might take another 5 to 10 years. The good news is that design innovations and material advancements are steadily pushing the timeline closer than I initially thought a few years ago.